Our Work

Explore our portfolio of precision mould design and engineering projects. From concept to completion, we deliver excellence.

Featured Projects

Highlighted work showcasing our precision engineering capabilities

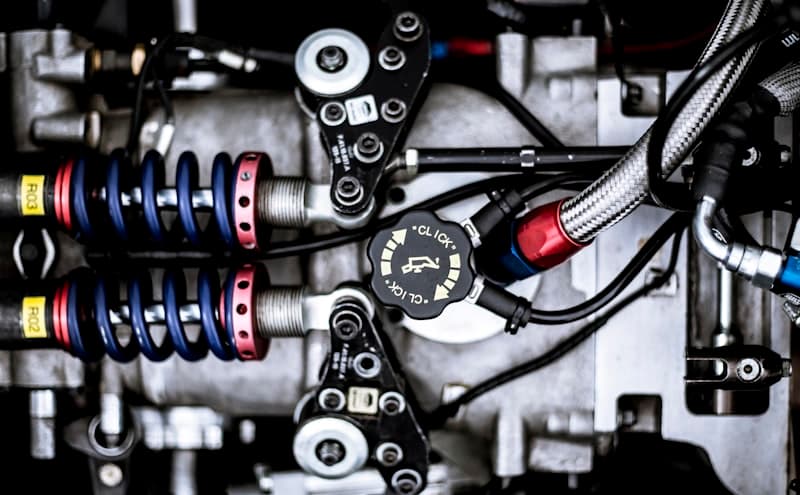

Multi-Cavity Dashboard Mould

Engineered a complex 2+2 cavity injection mould tool weighing 12 tons for Tier-1 automotive supplier. Delivered complete 3D design with 16-drop hot runner system, hydraulic core pulls, and cycle time optimization achieving 45-second production cycles.

Precision Optical Lens Tooling

Developed high-precision single-cavity mould for PMMA headlight lens with optical-grade SPI A1 polish. Achieved ±0.015mm tolerance using beryllium copper inserts and conformal cooling channels for zero-defect production.

More Projects

Additional examples of our diverse mould design and engineering work

IP Bezel Stack Mould

Designed 4-cavity stack mould configuration doubling output capacity. Integrated sequential valve gating and textured cavity surfaces for Class-A automotive interior finish standards.

HVAC Manifold Blow Mould

Created large-format blow mould tooling for 1.2m HVAC duct assembly. Optimized wall thickness distribution and parting line placement for seamless air-tight performance.

Consumer Appliance Tooling

Delivered 2-cavity production mould for high-volume appliance manufacturing. Engineered living hinge with 50,000+ cycle durability and gas-assist channels for sink-mark elimination.

EV Connector Insert Mould

Engineered 8-cavity precision mould for glass-filled PA66 connectors. Designed copper terminal insert overmoulding with ±0.02mm positional accuracy for high-voltage applications.

Console Family Mould System

Developed family mould producing 4 different console components in single shot. Balanced runner system and shared 24-zone hot runner reduced tooling investment by 35%.

Reflector Chrome Mould

Created vacuum metallization-ready reflector mould with mirror-polish cavities. Complex parabolic geometry achieved through 5-axis CNC and precision EDM processing.

Industrial Enclosure Mould

Designed IP65-rated enclosure tooling with integrated gasket groove and EMI shielding provisions. UL94 V-0 compliant material processing with zero flash requirements.

Door Trim Carrier Tooling

Engineered 8-ton single-cavity mould with 12 slider actions and 8 lifter mechanisms. Structural rib optimization reduced part weight 15% while maintaining stiffness targets.

500+

Projects Delivered

50+

Global Clients

8+

Industries Served

99.5%

Quality Rate

Have a Project in Mind?

Let's discuss how we can bring your vision to life with precision engineering and decades of expertise.